Insulating Boots/Shrouds

You are here: Home / Products / Boots/Shrouds

Insulating Boots/Shrouds

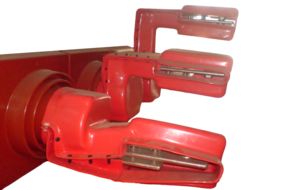

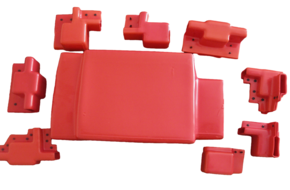

Busbar Shrouds/Boots are protective flexible PVC covers that will aid in insulating switchgear connections, busbars, and all types of electrical terminations up to 36 kv. The shrouds are made from polyvinyl chloride/plastisol material and we have customized proprietary formulations to suit both low & high voltage applications. These shrouds are inter- nationally acclaimed and are being made mandatory across the switchgear industry.

Salient Features of shrouds

* Flame retardant UL94/VO.

* Easily mountable & Re-usable.

* Wide working temperature range.

* Standard models and customized designs.

* Provides significant reduction in air clearances.

* High dielectric strength and good ageing properties.

* Cost effective solution to time consuming insulation tape.

* Reduces maintenance cost with less distribution interruption.

* Available in popular colors like red ,black , yellow, blue and transparent.

* Ensures electrical safety and helps prevent voltage related injuries during maintenance.

These Boots/shrouds are manufactured through dip moulding process under stringent ISO quality standards. The raw materials used in the process are in compliance to RoHS standards. We're a trusted supplier of these boots to both domestic and global OEM switchgear manufacturers We have a wide variety of boots to choose from or we can also provide tailor made solutions as per the customer requirement.

Product Showcase

-

Technical Specifications

Properties Category

Test Property

Standard Test MethodStandard Grades of Plastisol

VDSR,VDSR1,VDSB

Specified Values*Note : All the above tests are conducted as per testing plans - ref docs QA/QIP 02/8.2 REV NO 1 and QA/QIP 03/7.2 Rev No.00 at an accredited laboratory/ inhouse lab facility Electrical Properties Dielectric Strength ASTM D149/IEC 60243 5~15 kV/mm Volume Resistivity ASTM D257 1X109~1X1013 ohm Comparative tracking Strength IEC 60112 >600 V A.C Voltage with stand (Across the thickness shroud in oil) Phase to Earth 36kV/1 min Passed Mechanical Properties Tensile Strength ASTM D638/JIS K6723 6.3 ~11.8MPa Elongation ASTM D638/JIS K6723 300~500% Hardness ASTM D2240 60-85 Shore A Flammability UL-94 v-0 Self Extinguishes With in 15 Seconds Tear Strength ASTM D 624 >20N/mm Thermal Properties Thermal Stability at 900C/2 hours VD001 No Cracks/blisters/ bubbles on surface Freezing (-)400C/30 min No Cracks/blisters/ bubbles on surface Retention of Tensile Strength after thermal ageing at 1200C/120 hours ASTM D638/JIS K6723 >90% Retention of Elongation after thermal ageing at 1200C/120 hours ASTM D638/JIS K6723 >40% Chemical Properties Water Absorption <0.7% ASTM D570 Retention of Tensile Strength After Oil ageing at 700C/4 hours ASTM D638/JIS K6723 >80% Retention of Elongation after Oil ageing at 700C/4 hours ASTM D638/JIS K6723 >50% RoHS Cd,Pb,Hg,Cr6+,PBBs,PBDEs IEC 62321:2008 Not Detected Colour -- -- -- -- Black,Red